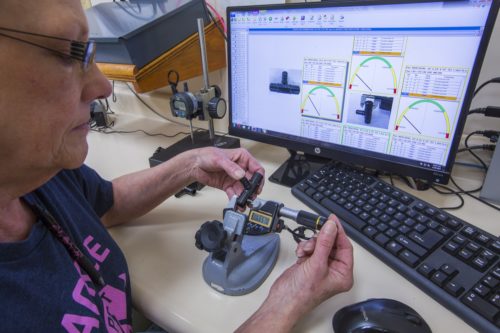

Port Erie Plastics offers our customers tremendous plastics engineering support. We have a staff of about a dozen degreed plastics engineers, and each customer is assigned a project engineer who serves as the chief technical liaison and offers plastics engineering support for all projects. Our customers have come to see this as a tremendous competitive advantage. Our engineers work hard to support our customers in various ways. They help source alternative resins that are more cost-effective, offer ideas to manufacture more efficiently, and deliver valuable insight on new tooling designs or existing tool modifications. We also have engineers who work primarily on automation projects using robotics and other technology for cost-saving projects. We design and build much of our equipment used for assembly and secondary operations. These can be workstations to install metal inserts and use vision systems for verification, or they can be refurbished 6-axis roots that drill more than a dozen precision holes in a part.

Port Erie Plastics offers our customers tremendous plastics engineering support. We have a staff of about a dozen degreed plastics engineers, and each customer is assigned a project engineer who serves as the chief technical liaison and offers plastics engineering support for all projects. Our customers have come to see this as a tremendous competitive advantage. Our engineers work hard to support our customers in various ways. They help source alternative resins that are more cost-effective, offer ideas to manufacture more efficiently, and deliver valuable insight on new tooling designs or existing tool modifications. We also have engineers who work primarily on automation projects using robotics and other technology for cost-saving projects. We design and build much of our equipment used for assembly and secondary operations. These can be workstations to install metal inserts and use vision systems for verification, or they can be refurbished 6-axis roots that drill more than a dozen precision holes in a part.

Plastics Engineering Support Offered:

- Interact in quoting stage of new jobs supplying technical information and expertise.

- Provide guidance to customers from initial concept and product development all the way through production to ensure success.

- Work with customers and tool shops to review mold prints, parts prints and models prior to mold build.

- Qualify new jobs until they are production ready, then ensure they meet the customer’s needs.

- Create and issue all procedures, documentation, and any relative information so jobs run efficiently in production.

- Work with customers to develop a quality control plan.

- Monitor each assigned project during production looking for continuous improvement.

- Our engineering staff has the ability to be creative thinkers with good communication and problem solving skills.

- Work under tight timelines with a high sense of urgency.

Case Studies

- Quick Turnover of Production & Tool Transfer

- Development of Custom Molded Polymer Fittings for the Plumbing Industry

- Process Redesign of a Structural Foam Molded HDPE Trench Drain for the Construction Industry

- Injection Molding of Custom Polypropylene and Elastomer Lids for the Cookware Industry

- Development of Safe Combination Dial for the Safe Manufacturing Industry